From its humble 1988 beginnings in Sherwood’s one-car garage in the alleyway behind his house to today’s state-of-the-art manufacturing facility located in rural Rancho Cordova, Ventana has grown up in Northern California. In a time proliferated by companies outsourcing the bulk of their manufacturing overseas, we at Ventana strive to bring all aspects of our manufacturing in-house.

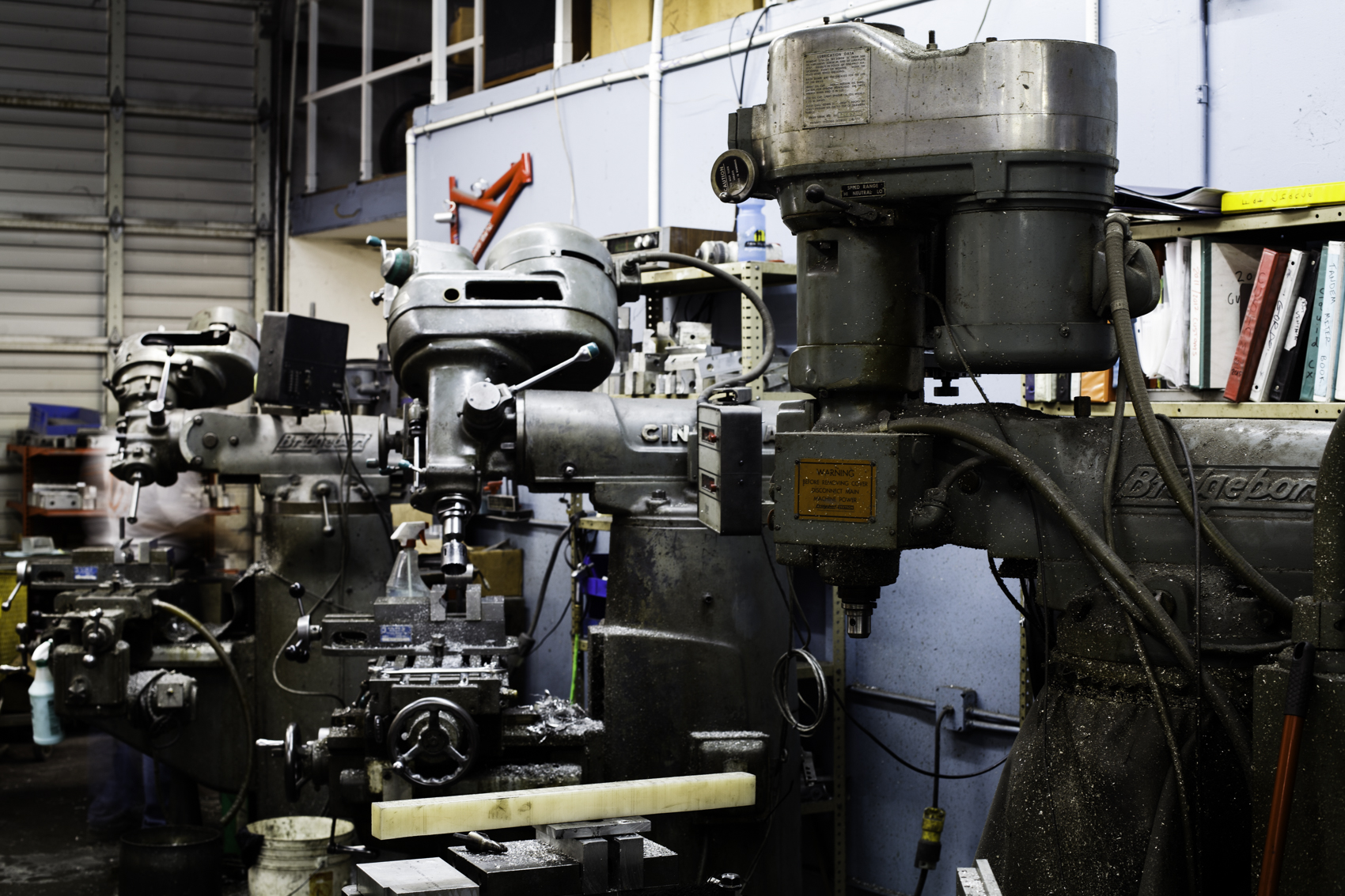

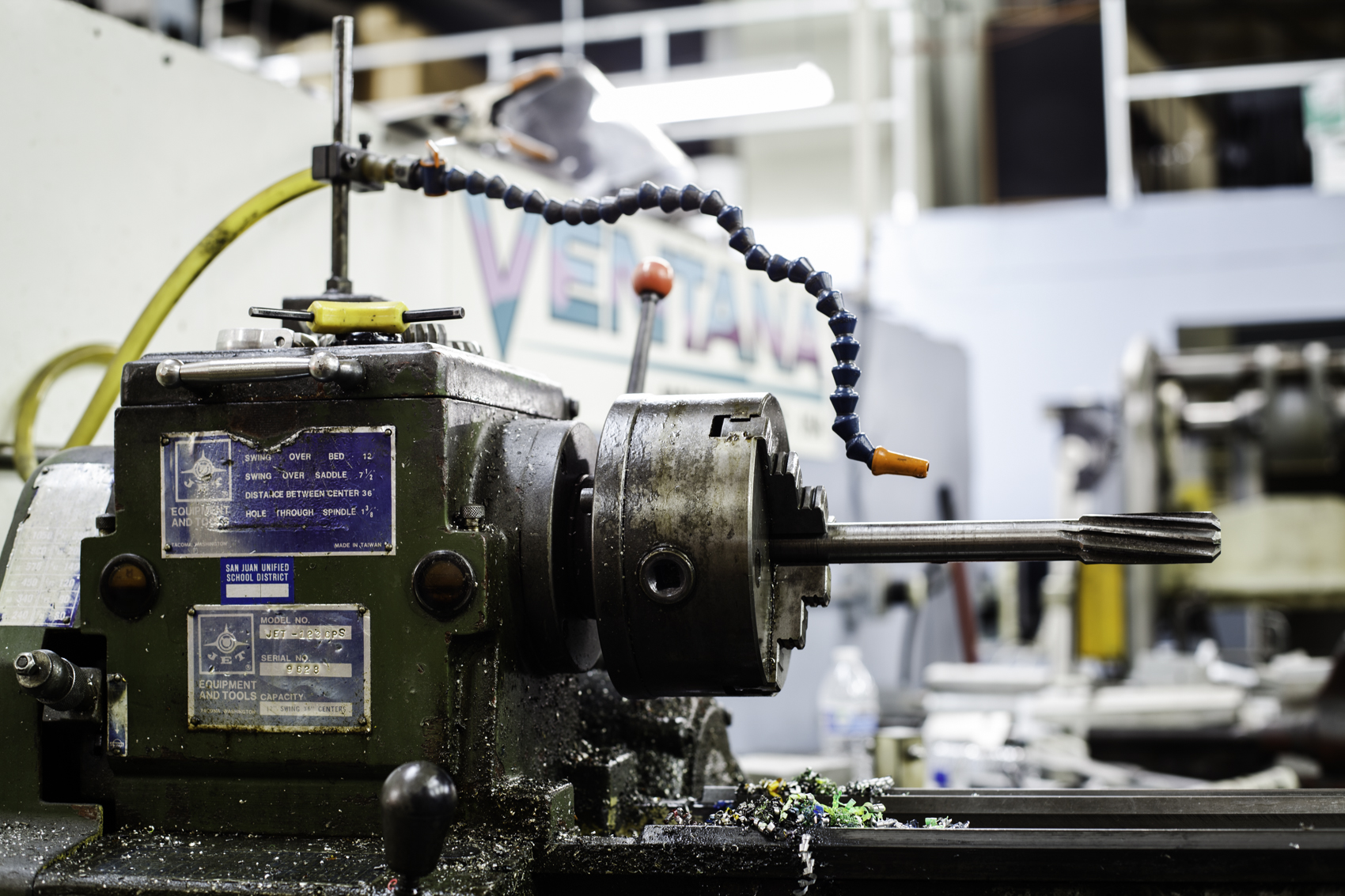

Since the early years in the old garage with the AC TIG welder, manual milling machine, vice, grinder and files, we have added CNC mills, square wave TIG welding machines, tube notching and coping equipment, parts tumblers and deburring machines, tube shaping and forming equipment, cleaning and weld-prep equipment, a full heat treating and powder coating facility complete with ovens and racking, our own design precision quenching system, hardness testing, powder storage, and precision alignment tooling. Our house is full, and we love it that way. We feel our all-inclusive in-house manufacturing yields the best products with the highest quality control and the shortest delivery times in the industry., while giving us the most flexibility in order to meet customer demands. And it is all meticulously carried out under the exacting watchful eye of Sherwood.

So when we say we build our bikes in-house, in the USA, we live and breathe it to our core.